At 3ERP, we obtain quite a few RfQs for precision machining jobs. We know how some parts involve far more treatment and a spotlight than Other individuals, but we keep on being committed to offering a fair value even for near-tolerance machining.

On top of that, the parts have superior accuracy and close tolerance finishes, so there is absolutely no require for secondary processes. This results in quicker production moments, rising the workshop’s efficiency and effectiveness.

In mass production, CNC machines are used to produce big quantities of similar parts with superior precision and consistency. This method is vital in industries including automotive, electronics, and buyer goods.

The aerospace industry has an extended-shared history with CNC machining. The machining of metal aircraft components happens at the best amount of precision.

There exists are a number of applications of CNC machining in many industries. No matter what industry you’re in, there will definitely be some sort of CNC machining practice which will fit your preferences.

In early November, 10 users of Congress urged the Biden administration to prioritize the curbing of exports of CNC machine tools to Russia. The letter famous a “troubling trend” of machine tools produced by U.S. allies, such as Taiwan, making their way to Russia’s defense industry.

Precision clean area finishes are other crucial necessities for healthcare industry tools. Quite a few of such, for instance bone screws and plates, are inserted into a affected individual’s human body and remain there. As a result, it is important in order that the individuals tend not to deal with soreness.

*There may be differences involving the info shown and the actual values, This could be confirmed because of the sales agent.

Machining Course of action: Immediately after almost everything has actually been assembled, the CNC machine starts cutting, shaping, or drilling product precisely alongside its programmed route with negligible human intervention necessary with the repetitive production of higher-precision solutions.

Numerous machine shops will request for the outset whether or not the customer requires precision machining, as this generally signifies that the RfQ needs added thought. If not, then the prerequisite for precision machining is often indicated by simply which include tolerances.

Our world is surrounded by complex technology evolving at a speedy charge. In daily life, we see lots of intricate parts, for example gears and elements inside of machinery, that makes 1 speculate what goes into manufacturing them.

After the aspect is produced using the precision machine, it might be taken off. Dependant upon the requirements, the part may very well be despatched for secondary processes which include grinding or sprucing.

The metal fabrication industry materials lots of secondary industries. It depends on CNC procedures like wire EDM cutting, laser cutting, waterjet and plasma cutting to cut huge website metal sheets. Other CNC plans can forge these metal sheets into any condition wanted.

CNC has totally adjusted the way in which tooling has made. CNC technology has paved the best way for custom-built dies and molds that could create any variety and condition of items.

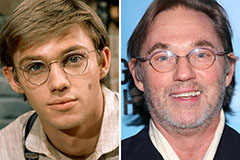

Daniel Stern Then & Now!

Daniel Stern Then & Now! Romeo Miller Then & Now!

Romeo Miller Then & Now! Nancy McKeon Then & Now!

Nancy McKeon Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now! Teri Hatcher Then & Now!

Teri Hatcher Then & Now!